Our workplace design team has a unique window into the changing nature of work, and the challenges that companies have keeping up with it. Every client meeting we attend, and every new design request we field, gives us a view of what’s really going on in today’s offices.

Late last year, we started to see some patterns emerge in the conversations we were having with clients about their workplace needs. And those patterns lined up with some trends and tactics we’d been incorporating into our projects.

It just made sense, then, to turn those patterns into a strategic roadmap our colleagues and clients could use as they are all rethinking what the workplace looks like. It examines the ways we need to shift our thinking about the roles, both functional and emotional, that offices play in workers’ lives today, with lots of examples and ideas to get begin the journey of workplace transformation.

We call the overarching approach “The Office as Ecosystem,” because it acknowledges that the workplace is an interconnected environment, where the well-being of one lifts the prospects of all.

If you’ve been grappling, as so many companies have, with a changed workforce and a not-so-relevant workplace, maybe a shift to ecosystem-thinking is in order.

Archivist Capital, Portland, Oregon

📸: Josh Partee

Check out the full strategic roadmap here, or watch this space for each installment, starting next week:

Part 1: The Office Gets Personal

Part 2: The Commute-Worthy Workplace

Part 3: The Not-So-Office Office

Part 4: New Ways to Meet

Part 5: Culture First Employee Engagement

(each Part will be hyperlinked once the blog post launches)

Banner photo: Buchalter, Portland, Oregon

📸: Magda Biernat

Living Our Hows Series

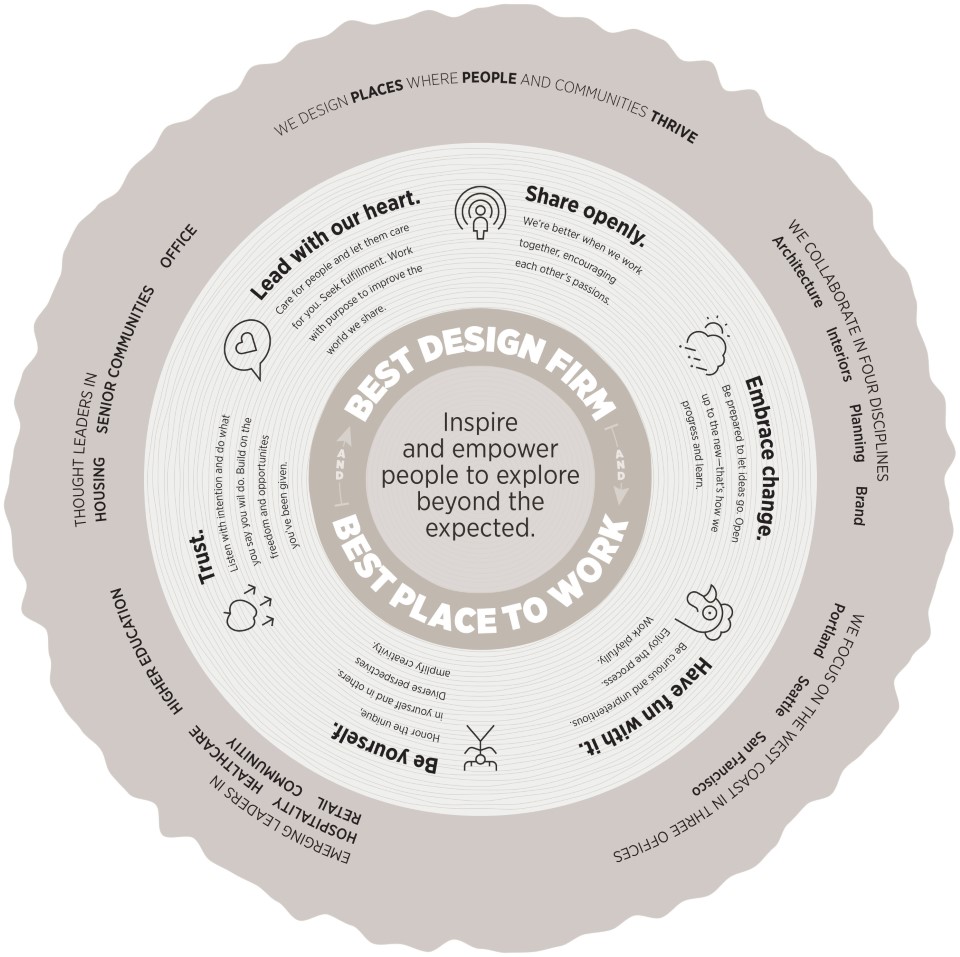

These are our Hows, the values by which we work and play. We created our Hows a few years ago through a decade-long process (stay tuned for a future post detailing that process!). We encourage everyone to show up in life and at work authentically, to seek connections and embrace the work we do with enthusiasm and flexibility. We’re a hybrid firm, and we work differently.

Our workplace design team has put together a six-part series that touches on our Hows and the way they come to life at AM. Click the links below to read each article in the series.

An Integrated Approach to Revolutionary Healthcare Design

Population health relies on more than simply treating sickness. Leading a healthcare shift to a value-based model whose viability depends on people maintaining their health, from a fee-for-service financial model, our client’s strategy embodies this pivot with a new healthcare center that integrates traditional clinical services with wellness facilities. The Providence Reed’s Crossing Wellness Center is a dynamic new healthcare facility that communicates warmth, healing, approachability — holistic architecture that sees people as more than patients. Community-oriented general fitness and wellness spaces act as bridges to more specialized functions like integrative health, dermatology, retail, physical therapy, imaging, women’s care, pediatrics, and more. Our design connects services with open, blended thoughtful architecture and interior design in an active urban environment.

Our hope: To help people get and stay healthy.

This radical new facility feels like it’s part of Main Street while feeling unlike anything else out there. To successfully integrate wellness with clinical services, we start by focusing on how to maximize operational benefits. Our design must communicate warmth and professionalism, relaxation with dynamic activity, aspiration, and inclusion. It’s not enough to simply combine traditional healthcare design with wellness. Our design concept must holistically communicate both. Because our client’s vision treats patients as complete people whose individual health is affected by diet, behavior, mental and emotional states, as well as physical abilities, our core interior design concept likewise promotes overall healthy living and wellbeing. Biophilic elements like natural light and exposed wood elements soothe visitors and decreases stress while they’re working out, learning about nutrition, or waiting to see their physician. Beautiful, integrated color palettes that fit each program will guide and orient people within the facility. Indoor/outdoor spaces further connect our design to its community and bioregion.

Our hope: A design that feels kinetic yet relaxing, empowering and healing, and completely revolutionary.

Go to the Providence Reed’s Crossing Wellness Center Project Page >>

Mass Timber: Harder Mechanical

A fifth-generation Portland family business, Harder Mechanical needed a new, modern headquarters to last them for another 80 years. Because reinvention tends to be part of their business—they gain expertise in the newest processes, be it mill work or high-tech manufacturing, and periodically transform themselves along the way—they were looking explicitly for an innovative showcase office.

Harder Mechanical building needed to stay rooted in the past while being built for the future. Because the owner is a mechanical and plumbing subcontractor and will self-perform their own scope, the Harder team became an integral part of the design process.

After learning who they are, how they view their work, and what they needed in a collaborative working session, our design encompasses a beautiful, durable brick building using renewable cross-laminated timber (CLT).

Their desire for an innovative approach—to not only the design but also the design process—led to an adapted integrated project delivery method. This allowed for close collaboration with Harder, the General Contractor, Swinerton, and their trade partners to achieve efficiencies and innovative construction methods that meet both design and construction goals.

The wish to showcase Harder’s own work and innovation led to exposed ceilings and exposed structure and mechanical systems. It is here where the Cross-Laminated Timber (CLT) structural system became a central design element. Utilizing Swinerton’s expertise in this area, the CLT simultaneously provides environmental benefits both to the occupants and in broader terms, along with time and cost saving installation.

Externally, the company’s rich history combined with the historic neighborhood led to the selection of both a durable and beautiful dark brick facade reminiscent of the surrounding context. This traditional material paired with a contemporary aesthetic allows the building to become part of MLK’s future whilst respecting its past. The building will last for decades, aligning with and improving the Elliott neighborhood in a way that’s both timeless and exceedingly modern.

Wynne Watts Commons

It is undeniable that housing insecurity affects millions across the United States. Rents are up and homelessness is on the rise. There are many factors that lead to these crises, including high housing costs relative to income, poor housing quality, unstable neighborhoods, or even health concerns and peripheral medical challenges and costs. Add to that the encompassing environmental impacts of climate change and a driving need to design and build more sustainably; we are faced with the need to take a more holistic approach to housing and accessibility to address our growing concern for the wellbeing of our communities.

We partnered with Albertina Kerr, an organization dedicated to supporting people experiencing intellectual and developmental disabilities (I/DD), mental health challenges, and other social barriers, to design the largest affordable and accessible housing project in the PNW. This joint project became one of the largest Zero Energy affordable housing projects in the U.S.

This four-story, 150-unit complex features 30 accessible units designed to provide adults with intellectual and/or developmental disabilities, earning 30% or less than the average median income, a place to live independently. Three units are available to families needing temporary housing and the remaining units are reserved for low wage direct service providers. This project showcases innovative technologies and design features readily available today to achieve better health outcomes for residents, minimal overall carbon emissions, and significant savings on energy bills. Energy-efficient features include a 660 KWh PV Array that will produce 727 MW-hours of electricity annually, enough renewable energy to fully operate the building with no utility cost to residents.

Albertina Kerr’s in-house staff were consulted to help inform the direction of features that are most useful to the residents. Smart-home integrations enhance safety and useability, and pull-out cook tops and mechanized upper cabinets help residents manage daily tasks. Thoughtfully integrated accessibility features include room darkening shades, RGB controllable lighting for chromatherapy mood management, and acoustically enhanced wall, floor, and ceiling construction that gives residents control of their space to prevent overstimulation.

Wynne Watts Commons is a huge step forward for sustainable and inclusive quality housing for some of the most vulnerable in our community.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

Mass Timber: Moda Tower Lobby

For our first mass-timber curtain wall in Portland’s Moda Tower, our goal was to design a canvas that activates the new public art at its heart. Effectively renovating a lobby for public art means more than just designing a white gallery box. The renovated lobby space requires a design that both elevates the artwork and functions for practicalities like circulation, lighting and climate, and code.

Before, Moda Tower’s lobby was like many others: small, dark, and relatively constricted. After decommissioning the long-standing previous artwork, we enlarged the lobby and its windows, and replaced the dark, dated floor with bright, crisp materials. The new 30 ft mass timber curtain wall is punctuated by wood-accented and fresh white walls. Warmth and light now invite visitors entering the lobby.

More than just a neutral background, the renovated Moda Tower lobby and our mass timber curtain wall are integral parts of the featured artwork, “Canopy” by Portland-based artist Joe Thurston. Coordinating with our client Unico Properties and Thurston, our team created a lobby redesign that captures the artist’s idea of a springlike forest canopy – the feeling of trees reaching toward each other against the sky.

We want visitors to look up as they enter. The glass leaves of Thurston’s tree-inspired artwork hang from the lobby’s ceiling 30 feet up, spotlighted by our expansive, not-quite-neutral gallery space. Outside, passersby are treated to a bright, vibrant extension of Portland’s forests. Using mass timber and other wood accents brings a unique natural beauty and warmth that flows through the space. Within the lobby, people should pause, even momentarily, to look up and find something unexpected.

Mass Timber: Skylight

Portland’s Central Eastside Industrial District is poised to transform its character and vibrancy. Designed to capture and elevate the essence of this historic industrial area, the 115,000 sq. ft. Skylight is our refined rendition of the modern office for creative technology and design professions. The structure is a mix of concrete, hybrid wood trusses, and steel, but the Nail-Laminated Timber (NLT) floor panels are the material binding the whole building together – offering both style and function.

We designed Skylight as two offices bridged by core and amenity spaces, like the wings and body of a butterfly. Our team used structural materials that unite the separate spaces with a raw, edgy, but down-to-earth aesthetic that appeals to creative office users. Exposed mass timber and hybrid wood trusses support a bright, open, and warm office environment. These natural elements contrast with cool concrete, steel framing, and visible architectural joints, adding visual activity and energy to the interior. An array of skylights at the heart of the building brings natural light to otherwise unaccessible spaces.

Use of NLT at Skylight also serves functional goals of our creative office design. The texture of this material has acoustic benefits for the space and exposing the natural finishes removed the added cost of applied interior finishes. We also coordinated with the MEP engineers and subcontractors to hide unattractive parts of typical office systems neatly beneath a raised floor, maximizing exposure to the beautiful natural wood and open space. Supporting mass timber with innovative, long-spanning hybrid trusses also allowed us to create a more flexible and unobstructed layout for existing and future tenants of the office building. Skylight used this method to reduce layout obstructions while maximizing versatility through 35’-40′ spans and only a single row of columns breaking up a 70’-80′ floor plates. To achieve this literal stretch from traditional 20’-25′ mass timber grids, our team designed an innovative, double glulam truss.

This project fired us up about new mass timber applications. While NLT is not as cutting edge as Cross-Laminated Timber (CLT) panels – a mass timber technology exciting the industry today – Skylight helped us explore and apply the full potential of NLT to establish a new standard for this evolving neighborhood. Its success relied on strong collaboration between the design, development, construction, and engineering team members, who include Turner Construction, DCI Engineers, Glumac, Shapiro Didway, Mackenzie, and Potestio Studio.

Mass Timber: The Standard at Seattle

With study spaces for every occasion, social areas, luxurious amenities, and ground floor retail just blocks from campus, The Standard at Seattle’s two high-rise and one mid-rise buildings will welcome students and locals. We took guidance from our client, Landmark Properties, one of the nation’s largest student housing developers, and inspiration from the neighborhood’s eclectic character to design student housing that fosters a community away from home.

In the mid-rise, Cross-Laminated Timber (CLT) construction will allow us to achieve higher ceilings than would otherwise be possible, with greater efficiency, durability, and beauty – three key reasons why we champion mass timber. Using mass timber from the Pacific Northwest also reduces the building’s carbon footprint. Wood on the exterior around the entry draws on the beautiful CLT inside and serves as a beacon for people arriving from the nearby train station. Since exposed mass timber is uncommon in Seattle student housing, we were excited to have the perfect opportunity to use this functional and stylish material at The Standard.

Standing at 26 stories, the two high-rise buildings will be amongst the tallest in the University District upon completion in 2023. Our design team used colors and materials to create a conversation between The Standard’s trio of buildings and its eclectic neighborhood. They conceptualized the high-rises as one form, pulled apart to reveal dark blue interior panels that shift in color as the sun hits the surfaces at different angles. The throughway with ground floor retail and afternoon sunlight will be a relaxing destination for the community. With gold details, the throughway is like a yellow brick road to the mid-rise building.

Amenities housed in the high-rise, but accessible to all residents, include a swimming pool, sauna/steam room, and rock climbing wall. All of these options will be easily accessible via a skybridge between the high-rises. The offerings caters towards providing residents as much choice as possible without having to travel far, a feature that our student housing experts know today’s young people desire. The interior design mixes natural elements with refined playfulness and warmth to keep the design appropriate for the city’s urban, tech-forward, and multi-cultural university students.

Celebrating Earth Day

Our Workplace Design Team is highlighting our integration of salvaged products and materials to celebrate Earth Day! We intentionally source and specify materials made with recycled content and naturally renewable resources in our projects. Beyond these materials there’s an abundant opportunity for reusing products that have already been manufactured, this keeps new items out of the landfill and is less energy-intensive than reforming old into new.

Salvaged goods are not always an obvious choice. A client, in financial services, was consolidating their office space in Seattle, which meant they had a lot of surplus furniture in great condition. The design team took inventory of the existing furniture and strategically incorporated over 140 pieces of furniture throughout multiple floors of the office space. This included conference chairs, task chairs, lounge furniture, and break room furniture. All of the unused furniture was donated to Green Standards to be resold or recycled. This project achieved its LEED certification in 2019!

Incorporating salvaged or unconventional materials in tenant improvement projects with fast schedules and tight budgets is the challenge we are looking for! For a project with Los Angeles Sanitation, we brought the concept of recycling into the design. Our designer researched recycled materials and discovered an artist who uses metal cans to create artwork. To exhibit this artwork, the designer, in collaboration with a casework fabricator, created a decorative panel to be installed into the face of the reception desk. A quote from the artist was included in the bid documents to make pricing by the contractor a breeze. Thoughtful planning and smart design allowed us to seamlessly incorporate a design element that reflected the client’s values. This was a success for all.

At 38 Davis, our firm’s office in Portland, we concepted our design to reflect our values. Sustainability and environmental stewardship are at our core. This is demonstrated by incorporating salvaged wood, from Pioneer Millworks. The salvaged wood material was applied in multiple locations – from ceiling clouds and wall cladding in the conference rooms to rolling benches and booth seating backs in our entry area. The selected wood contrasts the mass-timber construction, while maintaining the warmth and texture only wood can bring. The final project achieved LEED v4 Gold.

Mass Timber: 38 Davis

At 38 Davis, work and home is integrated through mass timber. Located in the heart of Portland’s Old Town Chinatown District, this building was the first ground-up construction to occur in the district in over a decade. One of the world’s first Leadership in Energy and Environmental Design (LEED) v4 certified developments, the building was designed with software guided fans and operable windows rather then relying solely on an HVAC supported air conditioning and heat recovery system. A testament to our commitment to sustainability, the 124,000 sq. ft. headquarters also features a greywater reclamation system and green roof that treats water and removes contaminants on site.

The six-story, mixed-use timber-framed building, which is home to our Portland headquarters, combines office, residential, and retail spaces. Expressing raw craft with care, the mass timber used in 38 Davis is more than warm and honest-it’s structurally sound and sustainable, lowering the building’s overall carbon footprint.

Utilizing a historic method of a traditional 3×4 tongue-in-groove floor panel system, the building features locally sourced Douglas fir timber beams and exposed columns, which can be seen from the inside as the beams come together in an energetic display of raw materials and craftsmanship that mirrors the work we do. This post-and-beam system allowed our team to create larger interior spaces, high ceilings, and large window openings, achieving our vision of a background “warehouse” space overlaid with a tech-forward workplace that is all parts beautiful and utilitarian, yet historic and comfortable.

As you enter the building, you flow through the ground floor communal thru lobby connecting entries along SW Davis and the semi-private mid-block courtyard with a custom backlit metal art was designed to represent the flow of the Willamette River as it moves through downtown Portland. In the lobby, reclaimed wood wraps the threshold to shared elevators guiding visitors from retail on the ground floor to office space on the second through fourth floors, and workforce housing on floors five and six.

We believe that diversity and sustainability are of paramount importance to the vitality of our lives, neighborhoods, and cities. Designing from an owner’s position, we seized the opportunity to create a vibrant, mixed-use development where we can live, work, and learn alongside local community members. The communal lobby, elevator, rooftop, bike storage, locker room and gym area create dynamic interactions between our staff, building residents, and University of Oregon students. A unique, inter-use greywater reclamation system filters runoff shower water from the upper residential floors and uses it to flush the toilet’s of the offices below, saving an estimated 202,800 gallons of water annually.