The SoMa district, home to the Ankrom Moisan San Francisco office, is a neighborhood perhaps best defined by transformation. Once an industrial district full of warehouses, a large influx of Filipino immigrants in the early to mid-century brought vibrant Filipino character to the area. This cultural heritage is visible throughout the neighborhood—street names such as Bonifacio, Rizal and Mabini honor Filipino national heroes. Filipino street art adorns the streets, from colorful murals to utility boxes decorated with the letters of the Filipino alphabet.

During the late-90s dot com boom, the ubiquitous warehouses of SoMa became desirable office spaces and it wasn’t long before the neighborhood was also filled with tech companies. Now, the vibrant Filipino cultural district shares space with the likes of Google, Facebook, and Salesforce. At the same time, a vast arts district featuring an array of museums and theatres has begun seeping into the neighborhood from the adjacent Theatre District. The result is a highly diverse neighborhood dense with offices, homes, businesses, and community.

Within this eclectic slice of the city, on 5th and Mission—just a block from our office—one of San Francisco’s largest new developments has just opened. Designed to become a cultural destination, the 5M development intends to serve as a sort of living room for the neighborhood. Covering 4-acres, the complex includes an office tower, a residential building, a cultural center and three small public parks.

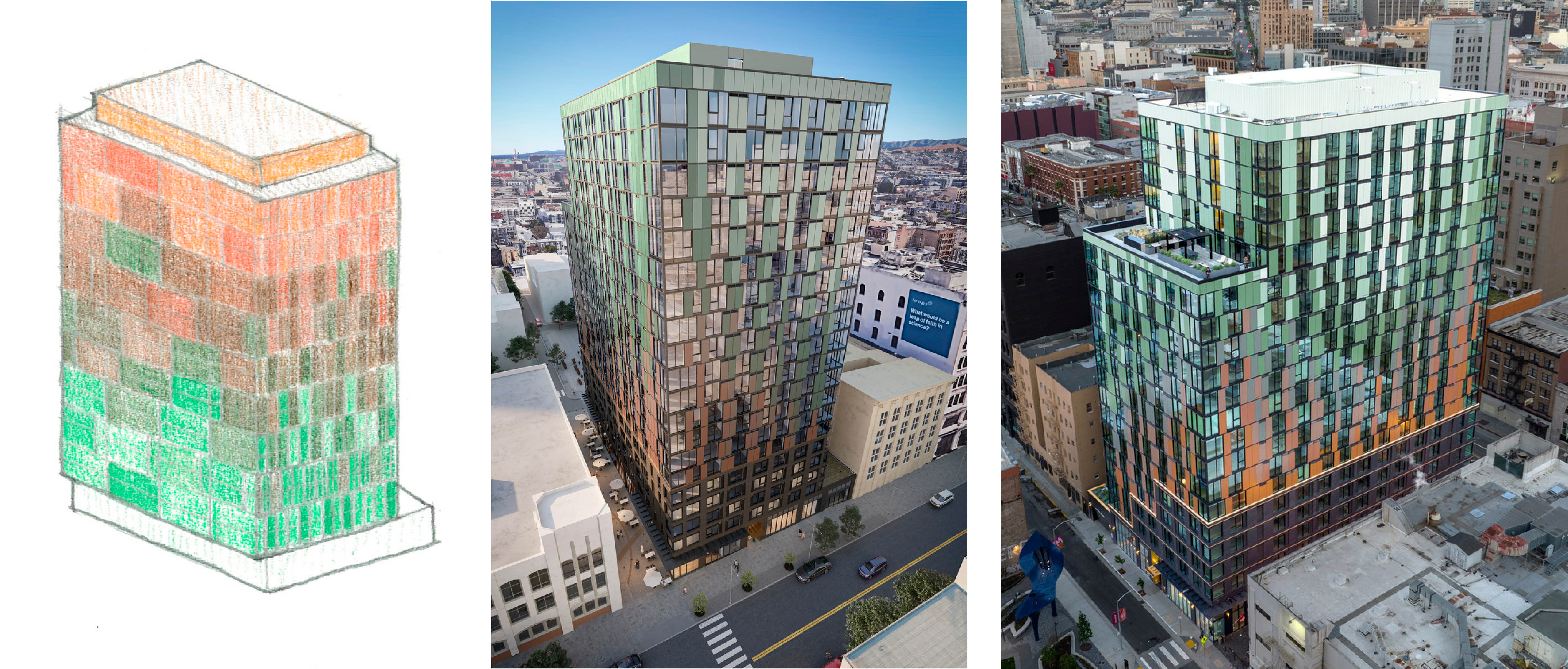

The 5M development, and each building within it, posed a formidable design challenge. Serving as architect for The George, 5M’s residential tower, our team was tasked with designing a high-rise that would blend into a hard-to-define, ever-fluctuating neighborhood. As residents of the neighborhood ourselves, our design was guided by our familiarity with and appreciation for the surrounding community.

The George’s design responds to the evolving, eclectic nature of the neighborhood by embracing imperfection and celebrating the cycles of time and growth. The tower’s shifting façade, inspired by the colors of aging copper, acknowledges the beauty in the marks left by time, weather, and use. At the street level, heavily textured metal accentuates strategic areas of the base, transitioning from a warm orange to a muted green—reminiscent of ocean water and rust. At the upper floors, variegated colored panels add interest to the simple massing and draw visitors’ eyes slowly upward along the height of the 20-story building.

The design evolution of the George, from sketch to rendering to final product

Our design evokes authenticity and a sense of place, using site-specific materials like brick and weathered metal panels that also raise the neighborhood’s design bar. “We are deeply honored to contribute to the vitality and culture of the neighborhood we call home” says Travis Throckmorton, AM Managing Principal and Principal-in-Charge of the project.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

The Principles of Cost Cutting

Q. What’s your top piece of advice for clients and the entire project team regarding cost efficient design?

A. The most important thing when you’re taking a hard look at cost-efficient design is building a strong, committed team. The owner can really help drive the ship by building a team that will support the goals that they’re advocating for. So, when they bring on a design team or a general contractor, it should be with a clear instruction that this project is prioritizing cost containment and you’ve been selected to help lead us in that direction.

Q. What impact does site selection have on project costs?

A. It can be huge. Some sites are quite simple. They’re flat, they’re unencumbered, they don’t have any nasty soil conditions, they don’t have any onerous zoning requirements. They don’t have a complicated design overlay. And then there are sites that are just the opposite. Maybe they have a lot of topography and require a subgrade system to get a buildable foundation for the building.

They might have really contaminated soil that requires a lot of upfront costs. If it’s in a historic district, there’s historic design overlays. Other design overlay districts require extra jurisdictional review. Anything that takes extra time, extra effort, extra coordination just creates extra work and stretches out the design schedule, which is going to cost the project more money at no significant benefit to the end-user or the developer.

Q. Is it possible to have elevated design while also reducing costs?

A. I know it sounds like it could be an oxymoron, but YES! We know we need to approach the project from a cost containment standpoint, and we want to have design at the forefront of every decision we make. It’s not cost containment first, design second; they should be parallel goals. We can still do excellent design and use those constraints around cost containment as a driving force for our creativity. How we can be creative within the constraints of cost containment – and letting that be our design challenge.

Q. What have you learned about designing efficient units in a way that prioritizes cost containment?

A. One of the biggest things is to design the units with as few variations as possible. We would minimize the number of unit types and then design each of those unit types as efficiently as possible. We also start by asking the question, How small can we make the unit and still make it livable and dignified and usable? The simple truth is square-footage costs money.

On Wy’East Plaza, we built a full-size one-bedroom mockup and loaded it with furniture and people and cabinets and asked, Is this too small? Okay, let’s move the wall out by 12” or 24”. How about now?

Once we felt like we’d found the lowest comfortable size by reducing the square footage we worked to put the whole building on a 24-inch module. This works really well with the scale of building materials. Then we worked to minimize inside and outside corners within the unit, each little moved saved. We tried to minimize the number of doors to reduce purchase and install time. so that there’s a door into the bedroom, a door to the bathroom and that’s it.

Q. How do materials and components factor in to cost cutting?

A. It’s important to work around standard material sizing from the industry so there’s not a lot of material waste and not a lot of cutting and fitting for the folks forming the concrete, the framing contractor, the drywall contractor, etc.

If everything’s designed around those material modules there’s less waste so they’re not having to buy as much overage. Then, you can take it more to the procurement level like, Are we buying materials that are locally sourced? Is the brick coming from Oregon versus Ohio? We look for those kinds of efficiencies wherever we can get them.

Q. Can you talk about leveraging the expertise of subcontractors. And how can their knowledge and experience help ensure design efficiency?

A. This is hugely impactful. How to do that is a trick that falls on a quality established general contractor, who has a lot of existing relationships with quality subcontractors. Those relationships can be leveraged to get subs to participate in the early design work not yet knowing whether they’ve won the bid.

Once you get the subcontractors engaged in the design process, then you start asking them, What would a building look like that has the most efficient plumbing system? What would a building look like that has the most efficient HVAC distribution system? If you could put your electrical room anywhere in the building to be the most efficient to install, and purchase equipment for, where would that be? If we do the roof this way is it more complicated than if we do it this way? What if you were king or queen for the day? And then you just listen. Really, nobody knows more about how buildings go together than the people who are on the job site doing the work, so it’s great if you can harness all that practical experience.

Q. What have you learned about setting a project up for successful approval during the design review process?

A. Well, one way to look at it is that we have to be humble designers. What I mean by that is if we design something and hope to get approval for it because it doesn’t exactly match the zoning or the design overlay requirements, and we’re going to have to ask for special compensation for a design move that we think is important but doesn’t match what’s allowed, then we’ve put another encumbrance on the project that’s going to cost time and money to resolve. So, we try to leverage our creative design abilities to do the best building we can within the existing set of approved design criteria. If we’re in a zone that has a particular set of design overlays, then we need to just work within those constraints and not try to use this project to flex our most impressive design edginess.

Click to read and download the Seven Principles of Cost Efficient Design, assembled in partnership with Walsh Construction and Reach Community Development.

Michael Bonn, Principal

Bringing Bigger Buildings to Smaller Jurisdictions

Over the last several years, more demand in smaller markets has resulted in increased proposals for larger scale developments. These jurisdictions have not previously had to review projects that utilize code criteria that are unique to larger building types.

From the construction permitting point of view, bigger buildings have different codes, and those codes have different interpretations from city to city, and sometimes reviewer to reviewer.

Jurisdictions are experts at the familiar but can often be resistant to the new. Given the role that building officials play in safeguarding the health, safety, and welfare of their community, a conservative approach to new code criteria is a reasonably common practice.

Our experience in jurisdictions with more complex code usage can help clients understand the way others have successfully worked with designers to implement unfamiliar strategies in code compliance.

Our expertise in larger buildings in bigger markets can be valuable with code analysis and interpretation in smaller markets, both from the designer and reviewers’ points of view.

We have consistently seen that building official/fire marshal engagement prior to submittal is key. Meeting early and often minimizes unforeseen issues arising during plan check review. Our history of discussions/solutions from multiple jurisdictions allows for specific issues to be flagged and addressed with real-world applications that have been proven to be successful.

We have found that when discussing podium construction there are several key elements to consider within the wood-framed components that differ from applications that do not include a concrete podium. Here are a few key items to consider:

- Type III: A wood construction with two-hour rated exterior walls, from the inside and out.

When building height exceeds 70 ft., this construction type allows for building heights up to 85 ft., and requires non-combustible exterior wall construction, commonly achieved through the use of fire-retardant treated lumber. Cladding and its support elements must also be non-combustible above 40 ft. Critical considerations include close study of the highest occupiable floor level based on fire access set-up point. If the lowest point of fire access results in a dimension to the highest occupiable floor level that exceeds 75 ft., then high-rise criteria become applicable. Cost typically limits high-rise construction to projects which far exceed 75 ft. height. Designers must consider this cost impact, especially when contemplating occupied roof decks, which some jurisdictions will allow to exceed the 75 ft. height, while others will not.

Project Example – Hudson on Farmer (Farmer Arts), Tempe, AZ (Framing construction, completed building)

- Type V: A wood construction with one-hour rated exterior walls from the outside.

When construction does not exceed 70 ft. this construction type allows for reduced costs and more easily managed fire resistivity criteria. Building area is limited, and in many cases fire walls within the building are required to compartmentalize the structure. For multifamily buildings, corridors penetrate these walls requiring rated opening protection. Although these walls add cost, they provide an opportunity to reduce the number of stairwells when used as horizontal exits between building compartments. Designers must consider how, and when, to use the horizontal exit tool, ensuring that no more than half of the required exits from a floor level are provided by horizontal exits. Additionally, these opening assemblies can be provided via several options, including manufactured assemblies, and custom specified components. Designers must consider the comparative costs of the different approaches and the capacity of the project’s general contractor to manage the installation of the selected approach.

Project Example – Modera Northgate, Seattle, WA. (Final rendering, floor plan compartment diagram)

- Type I: Podium/basement non-combustible construction of one, two, or three levels can be provided as a podium for multiple stories of wood construction above.

The ability to allow for the wood frame construction type of the building above to penetrate the podium reduces costs when stairs are able to be built of wood. Exterior wall framing must be built of non-combustible framing, however, when using metal studs, exterior insulation is often required to meet energy code insulation values. Using fire-retardant treated lumber can be an effective tool in allowing for exterior sheathing and cladding planes to align across the podium level.

Project Example – Canopy (Shea Aurora) Phase II, Shoreline, WA (podium construction photo, final rendering)

There is no one-size-fits-all solution. However, being able to work from multiple points of view allows for specific concerns to be addressed, while looking to past successes for location-specific solutions.

by Don Sowieja, Principal AIA, NCARB

An Integrated Approach to Revolutionary Healthcare Design

Population health relies on more than simply treating sickness. Leading a healthcare shift to a value-based model whose viability depends on people maintaining their health, from a fee-for-service financial model, our client’s strategy embodies this pivot with a new healthcare center that integrates traditional clinical services with wellness facilities. The Providence Reed’s Crossing Wellness Center is a dynamic new healthcare facility that communicates warmth, healing, approachability — holistic architecture that sees people as more than patients. Community-oriented general fitness and wellness spaces act as bridges to more specialized functions like integrative health, dermatology, retail, physical therapy, imaging, women’s care, pediatrics, and more. Our design connects services with open, blended thoughtful architecture and interior design in an active urban environment.

Our hope: To help people get and stay healthy.

This radical new facility feels like it’s part of Main Street while feeling unlike anything else out there. To successfully integrate wellness with clinical services, we start by focusing on how to maximize operational benefits. Our design must communicate warmth and professionalism, relaxation with dynamic activity, aspiration, and inclusion. It’s not enough to simply combine traditional healthcare design with wellness. Our design concept must holistically communicate both. Because our client’s vision treats patients as complete people whose individual health is affected by diet, behavior, mental and emotional states, as well as physical abilities, our core interior design concept likewise promotes overall healthy living and wellbeing. Biophilic elements like natural light and exposed wood elements soothe visitors and decreases stress while they’re working out, learning about nutrition, or waiting to see their physician. Beautiful, integrated color palettes that fit each program will guide and orient people within the facility. Indoor/outdoor spaces further connect our design to its community and bioregion.

Our hope: A design that feels kinetic yet relaxing, empowering and healing, and completely revolutionary.

Go to the Providence Reed’s Crossing Wellness Center Project Page >>

Mass Timber: Harder Mechanical

A fifth-generation Portland family business, Harder Mechanical needed a new, modern headquarters to last them for another 80 years. Because reinvention tends to be part of their business—they gain expertise in the newest processes, be it mill work or high-tech manufacturing, and periodically transform themselves along the way—they were looking explicitly for an innovative showcase office.

Harder Mechanical building needed to stay rooted in the past while being built for the future. Because the owner is a mechanical and plumbing subcontractor and will self-perform their own scope, the Harder team became an integral part of the design process.

After learning who they are, how they view their work, and what they needed in a collaborative working session, our design encompasses a beautiful, durable brick building using renewable cross-laminated timber (CLT).

Their desire for an innovative approach—to not only the design but also the design process—led to an adapted integrated project delivery method. This allowed for close collaboration with Harder, the General Contractor, Swinerton, and their trade partners to achieve efficiencies and innovative construction methods that meet both design and construction goals.

The wish to showcase Harder’s own work and innovation led to exposed ceilings and exposed structure and mechanical systems. It is here where the Cross-Laminated Timber (CLT) structural system became a central design element. Utilizing Swinerton’s expertise in this area, the CLT simultaneously provides environmental benefits both to the occupants and in broader terms, along with time and cost saving installation.

Externally, the company’s rich history combined with the historic neighborhood led to the selection of both a durable and beautiful dark brick facade reminiscent of the surrounding context. This traditional material paired with a contemporary aesthetic allows the building to become part of MLK’s future whilst respecting its past. The building will last for decades, aligning with and improving the Elliott neighborhood in a way that’s both timeless and exceedingly modern.

Wynne Watts Commons

It is undeniable that housing insecurity affects millions across the United States. Rents are up and homelessness is on the rise. There are many factors that lead to these crises, including high housing costs relative to income, poor housing quality, unstable neighborhoods, or even health concerns and peripheral medical challenges and costs. Add to that the encompassing environmental impacts of climate change and a driving need to design and build more sustainably; we are faced with the need to take a more holistic approach to housing and accessibility to address our growing concern for the wellbeing of our communities.

We partnered with Albertina Kerr, an organization dedicated to supporting people experiencing intellectual and developmental disabilities (I/DD), mental health challenges, and other social barriers, to design the largest affordable and accessible housing project in the PNW. This joint project became one of the largest Zero Energy affordable housing projects in the U.S.

This four-story, 150-unit complex features 30 accessible units designed to provide adults with intellectual and/or developmental disabilities, earning 30% or less than the average median income, a place to live independently. Three units are available to families needing temporary housing and the remaining units are reserved for low wage direct service providers. This project showcases innovative technologies and design features readily available today to achieve better health outcomes for residents, minimal overall carbon emissions, and significant savings on energy bills. Energy-efficient features include a 660 KWh PV Array that will produce 727 MW-hours of electricity annually, enough renewable energy to fully operate the building with no utility cost to residents.

Albertina Kerr’s in-house staff were consulted to help inform the direction of features that are most useful to the residents. Smart-home integrations enhance safety and useability, and pull-out cook tops and mechanized upper cabinets help residents manage daily tasks. Thoughtfully integrated accessibility features include room darkening shades, RGB controllable lighting for chromatherapy mood management, and acoustically enhanced wall, floor, and ceiling construction that gives residents control of their space to prevent overstimulation.

Wynne Watts Commons is a huge step forward for sustainable and inclusive quality housing for some of the most vulnerable in our community.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

Employee Spotlight: Jennifer Sobieraj Sanin

Empathetic, balanced, and calm—three words you’ll hear from Jennifer Sobieraj Sanin’s team if you ask them to describe her leadership style.

This month we’re excited to be spotlighting Jen, an architect and Managing Design Principal in our Seattle office. In her eleven years with AM, Jen has come to stand out as a female role model in architecture due to her unwavering advocacy for her teams, and for women in particular.

Jen approaches her leadership position with the intention to empower others. She creates an environment conducive to growth by “letting others get creative and do their best work,” as one of her colleagues has noted, “while at the same time staying engaged and providing feedback that guides the project in the right direction and helps you grow as a designer.”

We asked Jen to share her advice for emerging professionals in the industry. Here’s what she told us:

1. Be an advocate for yourself. Don’t be afraid to voice your opinions and ask for opportunities.

2. Find your mentor—someone who will offer guidance and stand up for you when you need it. Check in with them regularly.

3. Don’t change yourself to fit into a higher-level role. There is room for you to become a leader while doing what you love and are good at. A great leadership role will be flexible enough to match your skills and passions.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

Employee Spotlight: Ryan Miyahira

Ankrom Moisan Managing Principal Ryan Miyahira recently hosted AM’s second annual Pickathon, a video showcase of the firm’s many talented musicians.

We chatted with Ryan, who is a talented musician himself, to hear more about the inspiration behind AM Pickathon, an event he not only hosts but also created and produces.

Q. What’s your musical background and how did Pickathon come about?

A. I’ve been playing music since I was a kid. I had a band in high school and another in college, playing mostly 80s indie music. After college, my wife, Lara, and I started a band called the Hip Replacements. We cover old r&b and soul music. We’ve performed at several Ankrom Moisan Christmas parties and still play the occasional bar gig.

One of my favorite things to do is to go see live music. During the pandemic, we watched a lot of streaming concerts and I thought it would be fun to do an Ankrom version. I’ve had the chance to play music with other AM employees so I knew that we had a lot of musical talent in the firm. I wanted to show off those hidden talents in a fun way.

Q. How long have you been with AM and what has motivated you to stay?

A. I’ve been with AM for 22 years. Back in 2000 when I was looking for a job, the most important thing to me was to find the coolest group of people. I was looking for creative, hardworking, and fun people that wanted to do their best, but were also easygoing enough to have a good time while doing it. That’s how I landed at AM. I’ve noticed that it seems to perpetuate itself—a group of good people is like a magnet that attracts more good people. That’s what has motivated me to stay for so long.

I also appreciate that it’s been a very supportive and fun environment where you can make your own way. There’s so much room for passion and exploration at AM. If you have an idea, like hosting a Pickathon, and the drive to do it then the firm will support it.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

Virtual Reality

Our incredible in-house visualization team is testing out some VR upgrades! Virtual reality has proven to be a valuable design tool for our teams so we’re expanding our capabilities with new equipment. Soon, we’ll have upgraded VR stations in each of our three offices.

So, how do we use VR?

VR allows our designers to get a true sense for the scale and feel of a space as they are designing it—adding efficiency and improving end results. For instance, virtually walking through a unit during the programming stage helps inform early layout and square footage decisions so that costly last-minute changes can be avoided and the resulting unit design will better meet pricing expectations.

It also helps our interior designers to visualize details previously left to the imagination such as how flooring patterns would look repeated on large scales or how the placement of a lighting fixture might affect the overall feel of a space. Getting these small details right leads to a more cohesive and intentional end-product.

By providing our clients the opportunity to experience different design variations within their projects, we can aid their decision-making processes. While designing Olympic Tower, a luxury senior-living high-rise in Seattle, we gave our client, Transforming Age, the opportunity to tour the building two years before the project even broke ground. After using VR to experience the tower’s premier amenity, a performance hall, the client realized the scale was not what they had imagined. As a result, we increased the ceiling height, changed the dimensions of the stage and adjusted the lighting. VR helped convey the nuances of the design so the client could make informed decisions on where to allocate resources, and they didn’t have to experience any surprises during construction.

by Mackenzie Gilstrap, Sr. Marketing Coordinator

Mass Timber: Skylight

Portland’s Central Eastside Industrial District is poised to transform its character and vibrancy. Designed to capture and elevate the essence of this historic industrial area, the 115,000 sq. ft. Skylight is our refined rendition of the modern office for creative technology and design professions. The structure is a mix of concrete, hybrid wood trusses, and steel, but the Nail-Laminated Timber (NLT) floor panels are the material binding the whole building together – offering both style and function.

We designed Skylight as two offices bridged by core and amenity spaces, like the wings and body of a butterfly. Our team used structural materials that unite the separate spaces with a raw, edgy, but down-to-earth aesthetic that appeals to creative office users. Exposed mass timber and hybrid wood trusses support a bright, open, and warm office environment. These natural elements contrast with cool concrete, steel framing, and visible architectural joints, adding visual activity and energy to the interior. An array of skylights at the heart of the building brings natural light to otherwise unaccessible spaces.

Use of NLT at Skylight also serves functional goals of our creative office design. The texture of this material has acoustic benefits for the space and exposing the natural finishes removed the added cost of applied interior finishes. We also coordinated with the MEP engineers and subcontractors to hide unattractive parts of typical office systems neatly beneath a raised floor, maximizing exposure to the beautiful natural wood and open space. Supporting mass timber with innovative, long-spanning hybrid trusses also allowed us to create a more flexible and unobstructed layout for existing and future tenants of the office building. Skylight used this method to reduce layout obstructions while maximizing versatility through 35’-40′ spans and only a single row of columns breaking up a 70’-80′ floor plates. To achieve this literal stretch from traditional 20’-25′ mass timber grids, our team designed an innovative, double glulam truss.

This project fired us up about new mass timber applications. While NLT is not as cutting edge as Cross-Laminated Timber (CLT) panels – a mass timber technology exciting the industry today – Skylight helped us explore and apply the full potential of NLT to establish a new standard for this evolving neighborhood. Its success relied on strong collaboration between the design, development, construction, and engineering team members, who include Turner Construction, DCI Engineers, Glumac, Shapiro Didway, Mackenzie, and Potestio Studio.